How to improve gas strut handling

Mounting and practical considerations.

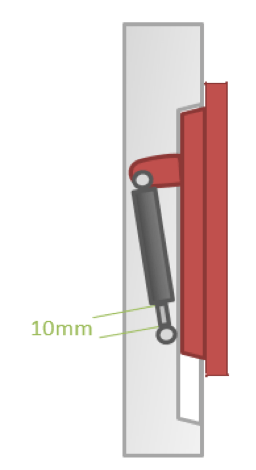

Unused Stroke

Camloc’s preference when positioning is to allow 10mm of unused stroke. The reason for this is to allow for the stack up of manufacturing tolerances in the application and prevent the gas spring from bottoming out before the lid is fully closed.

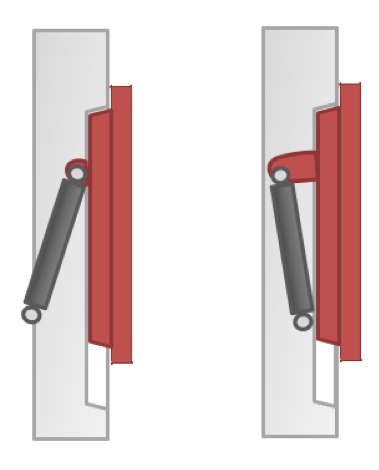

Preventing Instant Lift

Positioning the moving mounting point so that it creates an over-centre condition when the lid is closed will aid in reducing instant opening of the lid.

The images below show examples of spring positions that will lead to instant lift (on the left) and one that is over-centre and will reduce the potential of instant lift (on the right).

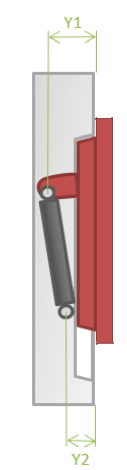

Reducing Handling Forces

To help reduce handling forces, the following strategies can be used:

- Move the mounting point Y1 closer towards the pivot by reducing the stroke.

- Consider whether the opening angle could be reduced.

- Move fixed mounting point Y2 to a more suitable location.

For more technical information on mounting and other commonly asked queries, head over to our whitepapers section. For information on our product range, please visit our Products Page.