What do the friction locking compression gas struts range ‘Stop and Stay / Stop and Stay+’ do?

Friction Locking Compression Gas Struts have internal pre‐set friction control valve gas struts counterbalances the weight of the application, enabling multi‐position holding without the need for any manual adjustment. This puts screens or other appliances exactly where you need them for however long you want them there. The specially‐designed internal friction valve is pre‐set to your application’s weight, making Friction Locking Compression Gas Struts quick and easy to fit.

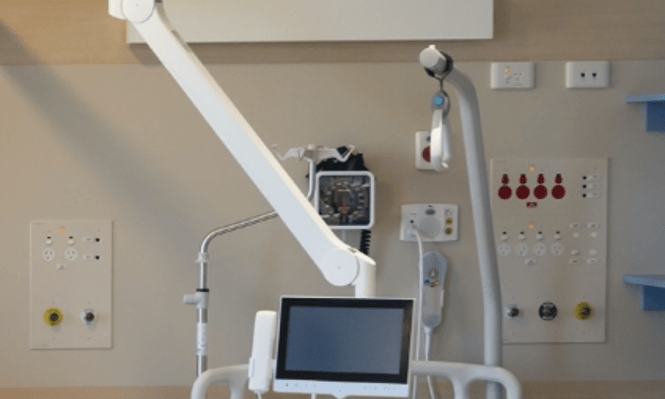

Our range of stop and stay products provides the user with total control over position for applications. This allows the user to raise, lower and set the application in any position using the minimum amount of effort, and in quick time. They are not locked in position like the Blocklift product, they are simply held until the user moves them again. Stop and Stay gas springs are ideal for a wide variety of applications, such as canopies, monitor arms, acoustic hoods, delicatessen counters, sunbeds and many more.

How does the Friction Locking Compression Gas Struts (External & Internal) – Stop and Stay / Stop and Stay+ work?

Our Friction Locking Compression Gas Struts are easy to fit with simple adjustment to determine the correct level of support. Once fitted, fingertip control allows movement to any position required. In the case of the Stop & Stay product, the locknut is adjusted to suit the application’s weight, thereby applying a ‘stick-slip’ friction to the rod.

In the case of the Friction Locking Compression Gas Struts, this has an internal locking mechanism which is factory set, and ideal for installation when used in a volume manufacturing environment.

Will it work for my requirements?

We offer a bespoke service, and our team of experienced engineers will work with you to provide gas spring solutions, even if it is outside the standard type and sizes.

Camloc Motion Control Ltd prides itself on its service to customers, with design engineers on hand to work with you using the latest CAD/CAE techniques. Recognising that no two applications are the same, Camloc Motion Control Ltd provides engineered solutions to meet your exact requirements.

Our products page has more information about the various range of solutions we provide.

Talk to one of our team on +44 (0)116 274 3600 or fill in the Contact Us form and we will get back to you.

What sizes do you offer?

Gas struts are commonly referred to by their size. The three sizes for Stop and Stay gas struts are 6-15, 8-18 and 10-23. For the Stop and Stay+ there are two sizes available, 8-18 and 10-23. The sizes directly relate to the diameter of the rod and the tube, for example an 8-18 will have a rod diameter of 8mm and a tube diameter of 18mm.

We also offer a wide range of bespoke sizes depending on your requirements.

How does Camloc operate?

Continuous investment in our staff and the latest hardware keeps us at the forefront of our industry, ensuring we continuously adopt the latest manufacturing processes from our facility, and we successfully problem-solve for our customers. We continue to enhance and evolve our production processes using lean manufacturing methods, something we have been doing since 2001.

We deliver high-quality products that cover a wide range of industry sectors, across the UK, USA, Europe and around the world.

Get in touch via our Contact Form or call us on +44 (0)116 274 3600

To access more information on installing, maintaining and technical data about gas spring, damper and motion control solutions – head to our Help Centre.