Safety, innovative design and protection are all key requirements within military applications. That is why our engineers and highly skilled team members will work closely with our customers in the military sector undertaking design, development, prototyping and production of projects requiring assistance with motion control.

It is this attention to detail and focus on durability, and the protective requirements of this sector, that means that we are able to offer best-in-class support through all stages of the process. Our team of engineers understand that, at the heart of the design brief, is the key deliverable of protecting vital staff and crew members in a military setting. We are dedicated to designing and creating innovative motion control solutions that do just that. We’ll push the limits of innovation while never forgetting the essential requirements of these solutions.

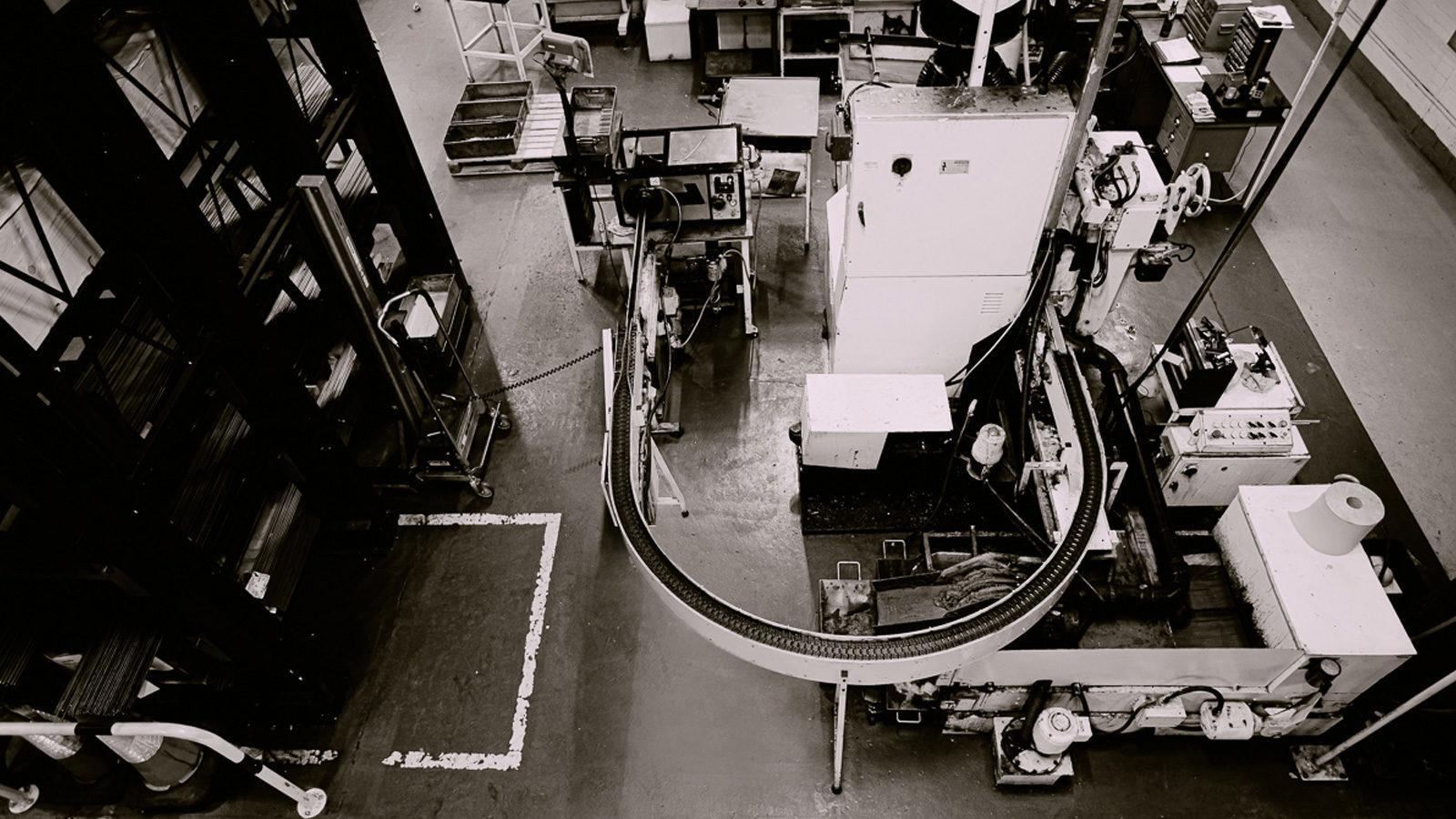

Offering modern manufacturing techniques from our UK factory, we have the capabilities to work with customers from concept design. This proves highly-effective in an industry where advancements and technological innovations are commonplace.

At Camloc Motion Control, we have worked with industry leaders in the military sector on specialist projects, and have offered assistance with products of ground-breaking design and exceptional quality, suited for everything from military ships to submarines. From blast mitigation seating to armoured vehicle doors, we have experience of designing and manufacturing a variety of elements that are essential to the military sector.

You can learn more about the range of other sectors we work with here.

Where gas springs and dampers can be found within the military sector

The sheer number of gas springs, dampers and other solutions found in the military sector is both vast and impressive. From military vehicle and equipment gas struts, shocks and dampers to naval vessel gas struts, shocks and dampers, the possibilities are endless. At Camloc, we understand the complexity and essential requirements for protection that characterise this industry, meaning we never compromise on meeting the exacting standards required.

Naval Vessel Gas Struts, Shocks and Dampers

Our team of highly-qualified engineers understand that naval vehicles are continually advancing, and with this continuous advancement comes a wide array of motion control issues and opportunities for development. However, with this advancement, there can be no compromise on the solution’s ability to be robust, innovative and critical to the success of the mission.

The bespoke solutions we offer enable us to work with you from beginning of concept design to provide the best possible solution for your project or requirements. We also have the capacity to work with you at any stage during the project. If a motion control issue arises late on, we will always work to provide the best possible fit. Our customer care and commitment to you after we’ve produced the solution is what separates us from the competition.

Our standard Swift and Sure range is an entirely self-contained, maintenance-free, hydro-pneumatic ram that is charged under pressure with an inert gas, nitrogen. This has proven to be an ideal solution for lift assistance and a controlled rate of movement on crew beds, having previously been used on the type 45 Destroyer.

When undertaking this kind of engineering and design work, it’s essential to understand that military ships and submarines can operate in some of the harshest environments on the planet. That is why our gas springs and rods can come as 316L stainless steel and can withstand the required extreme conditions, as durability is built into every element of the design.

These products are subjected to rigorous testing, which includes more than 1,000 hours of salt-spray testing. As they are made with a specially-prepared chrome-plated rod surface finish for additional protection, they perform exceptionally well in many different types of ocean conditions where Navy vessels can be found.

Blast Mitigation Damper

Our blast mitigation dampers are used on military vehicles to assist in minimising injuries sustained by personnel involved in vehicle mine incidents, increasing the chances of crew member survival.

We manufacture products that are used day-in, day-out in conflict zones around the world. Day after day, these products help to protect and save countless lives.

Whether the main mitigation device, or forming part of a wider protection system, our gas struts and dampers help deliver outstanding DRIz performance and protection levels according to STANAG 4569.

At Camloc Motion Control, our standard range of gas struts and dampers are suitable for many different applications, and our incredible team can even tailor bespoke solutions for you, as and when needed.

You can learn more about the range of other sectors we work with here.

Examples of how our gas springs provide solutions within the military vehicle sector

It’s fascinating when you realise just how many ways gas springs are used within the military vehicle sector. The solutions provided are required to meet conditions and design briefs entirely unique to this sector. For example, all solutions must be able to withstand extreme weather conditions and serious damage while serving the essential role of protecting the team inside.

The list where gas springs and dampers can be used goes on, but here are a few of the key specific applications:

- Blast mitigation seating

- Driver and crew seating solutions

- Armoured vehicle doors / access panels / tailgates

If you have a particular project in mind, don’t hesitate to get in touch with us.

Bespoke Design

At Camloc Motion Control, all our products are designed to meet our customer’s exacting needs and standards, and our team of experienced engineers will work with you to provide gas spring solutions. We pride ourselves on our service to customers, with design engineers on hand to work with you using the latest CAD/CAE techniques. Recognising that no two applications are the same, we provide engineered solutions to meet your exact requirements.

Our products in this sector:

Our gas springs and dampers are suited for powerful tracked and wheeled military vehicles facing sophisticated land forces across a wide range of operating environments.

Through our bespoke solution offering, our engineers will work with you to find the best possible solution to meet the precise standards required in military vehicles. With safety being imperative, because of how military vehicles are used and where they are found, we understand the importance of providing a product of the highest quality, which provides the best possible solution for your application.

Our wide product offering enables us to provide a solution for many applications on military vehicles. For example, our lockable gas spring – the Blocklift – is ideal for Commander, Driver/Crew and Gunner seating. Being fitted with a special locking valve which will only allow the spring to be moved when the pin is pressed, enables the gas spring to be stopped at any position.

Our standard Swift and Sure can be utilised to provide a controlled rate of movement and lift assist for applications that have the capacity to cause injury if a gas spring is not featured. Armoured vehicle bonnets, doors, boots and tailgates are primary examples of heavy-duty military vehicle applications where ease-of-use and safety for the end-user is crucial.

We’re here to help you and answer any questions you might have. If you’d like to speak to a member of our team, just give us a call on +44 (0)116 274 3600 or fill in the Contact Us form and we will get back to you as soon as we can.

How does Camloc operate

Understanding the complexities of projects involving the manufacturing in the military sector is what our team does best. Boasting a 99% on-time delivery rate and competitive lead times – coupled with our expert technical advice and engineering support – this is what separates us from the competition.

Our expert team have extensive experience within the military sector, working closely with industry leaders to successfully deliver a variety of projects. Whatever your project requirements, we’ll be with you every step of the way.

Continuous investment in our staff and the latest hardware keeps us at the forefront of our industry, ensuring we continuously adopt the latest manufacturing processes from our facility, and we successfully problem-solve for our customers. We continue to enhance and evolve our production processes using lean manufacturing methods, something we have been doing since 2001.

We deliver high-quality products that cover a wide range of industry sectors, across the UK, USA, Europe and around the world.

“Working with Camloc is easy and feels like working with other members of our team, they really understand how we work and what we want to achieve.”

James Smith – Industrial Sales Manager – Clarendon Specialty Fasteners.

For guidance on installing, mounting or maintaining gas struts, please see the Help Centre section of our website.