What do hydraulic dampers do?

Designed to control the movement, speed or to reduce vibration in a range of applications, our dampers are found across a range of environments, from those that enhance comfort to those that save lives.

Dampers can be configured from simple extension and compression dampers, either with or without gas, through dampers to bespoke blast mitigation solutions used in military applications.

How does the hydraulic damper work?

If movement needs to be controlled, an object stopped or vibration eliminated, this is likely the product you need.

Hydraulic dampers are self‐contained, maintenance‐free units that control the motion in applications requiring velocity control, deceleration control or to absorb shock impulses. They are designed and engineered to absorb, meter and control kinetic energy.

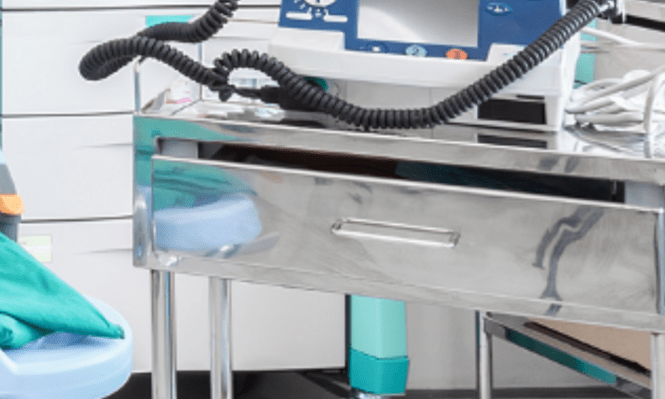

Available in both carbon steel and stainless steel, our dampers are specifically-designed to control or influence the characteristics of movement of the application. Applications requiring such control include CPR beds, weight adjustment dampers, automatic gate and lid closures.

Camloc specialise in the design and manufacture of hydraulic dampers. Available in a wide variety of materials and configurations, we do not simply make dampers that are gas struts with more oil and no gas. We have the experience, knowledge and ability to design and manufacture dampers for the most demanding of applications, whether that is mono tube or twin tube dampers.

Compression, extension, both directions or through dampers, we have the expertise to develop the right solution that is used within thousands of critical applications around the world.

For guidance on installing, mounting or maintaining dampers, please look at the [Help Centre] section of the website.

The hydraulic dampers are available in carbon and stainless steel. These compact, reliable units operate at a temperature range from ‐40c to +100c, making them highly durable and maintenance‐free.

Will it work for my requirements?

We offer a bespoke service, and our team of experienced engineers will work with you to provide hydraulic damper solutions, even if it is outside of the standard type and sizes.

We pride ourself on our service to customers, with design engineers on hand to work with you using the latest CAD/CAE techniques. Recognising that no two applications are the same, we provide engineered solutions to meet your exact requirements.

Our products page has more information about the various range of solutions that we provide.

Talk to one of our team on +44 (0)116 274 3600 or fill in the Contact Us form and we will get back to you.

What sizes do you offer?

Like gas struts, dampers are commonly referred to by their size. Unlike gas struts, all our hydraulic dampers are designed bespoke to the customer’s needs. With so many options available, we do not stock a range of standard sizes through our distributor network, but instead work with the customer to develop the correct solution for their needs. These can range from 6mm rod diameter up to 28mm tube diameter.

How does Camloc operate?

Continuous investment in our staff and the latest hardware keeps us at the forefront of our industry, ensuring we continuously adopt the latest manufacturing processes from our facility, and we successfully problem-solve for our customers. We continue to enhance and evolve our production processes using lean manufacturing methods, something we have been doing since 2001.

We deliver high-quality products that cover a wide range of industry sectors, across the UK, USA, Europe and around the world.

Get in touch via our Contact Form or call us on +44 (0)116 274 3600

To access more information on installing, maintaining and technical data about gas spring, damper and motion control solutions – head to our Help Centre.