What does the fixed force compression gas strut ‘Swift and Sure’ do?

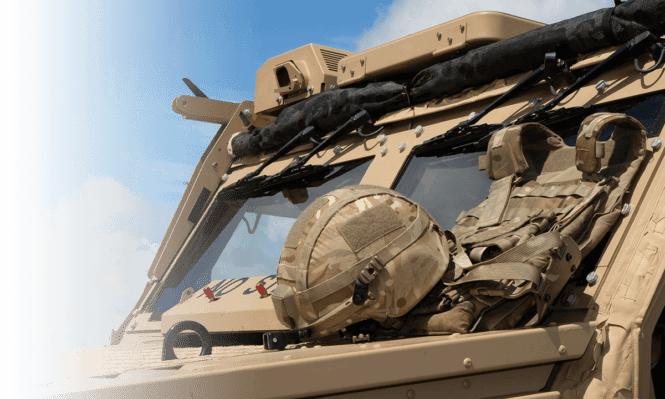

Designed to lift heavy weights effortlessly and safely, our standard fixed force gas struts are found on vehicles, machine guards, access panels, lockers and lids. But, in reality, there is an almost limitless number of applications this range can be used on.

Camloc’s gas springs offer an innovative solution to the most demanding requirements. Fixed force gas springs can be set at any force required within the range to ensure the optimum performance for each customer application. By adjusting forces, oil levels, extension velocities and oil types the result is a level of precision unparalleled by any other type of spring. They can be used to provide a gentle touch or withstand harsh impacts and heavy loads.

Our standard gas strut has extensive options and a wide range of customisable features, including connectors, brackets, shrouds and stop and stay functions. The gas strut is entirely self‐contained, maintenance-free, and is charged under pressure with an inert gas (nitrogen).

What are the key benefits of Fixed Force Compression Gas Struts?

- Fully customisable

- Factory set to required force

- Optional variable force adjustment

- Maintenance-free

- Fully self-contained unit

- Sized to your application

- Compact design with high durability and reliability

- Available in carbon steel and stainless steel

- Compression Gas Strut Available in a Range of Sizes

How does the standard fixed force gas strut work?

Gas struts make up a wide variety of the motion control solutions that we rely on each day.

If you have a project where an item needs to be lifted, held open or counterbalanced, one of our fixed force compression gas struts could be the answer.

This is an entirely self-contained motion control solution which is charged under pressure with an inert gas. It has the characteristics of a compression spring which, when partnered with a small change in force as it extends, provides a controlled rate of movement.

The ‘Swift and Sure’ is the most versatile and customisable product that we manufacture here at Camloc. Alongside alterations to physical diameters, lengths and forces, a whole host of other parameters can be adapted to ensure the optimum solution for your specific needs. This includes oil levels and types of oils to change the handling, performance and damping characteristics of the gas strut, piston designs to increase or slow down the extension speed, and material selection to allow the product to be used in particular environments, for instance through the use of non-magnetic materials.

If you are looking for guidance on installing, mounting or maintaining gas struts, visit our Help Centre today.