At Camloc Motion Control, our range of gas struts and dampers are well-suited to a wide variety of industrial automation applications. What separates us from the competition is our ability to support our clients throughout the design, creation and post-production process. Our team of highly-skilled engineers is committed to both you and your project, and will work closely with you to determine the best solution for your requirements. At Camloc, we understand that no two projects or engineering briefs are the same, which is why we tailor our solutions each and every time to maximise success.

Our team specialises in the design and creation of made-to-order products. We have full control of the manufacturing process from our UK base and this allows us to maintain our high and exacting standards. This is particularly important when we are faced with the machine uptime and reliability requirements required in the industrial automation sector.

Working with industry-based design engineers, we’re able to develop applications as diverse as the equipment they’re being used within. We understand the unique challenges of working in the industrial automation and machinery sectors, and that no two projects are the same. Your solutions won’t be, either.

Our team of dedicated engineers will work with you to find the best possible solution for the challenges of your design brief. We’ll take the time to consider the risks or consequences of each solution, which means we can use our products to improve the motion of a food packaging machine or provide lift support to an access panel used when servicing or maintaining it.

You can learn more about the range of other sectors we work with here.

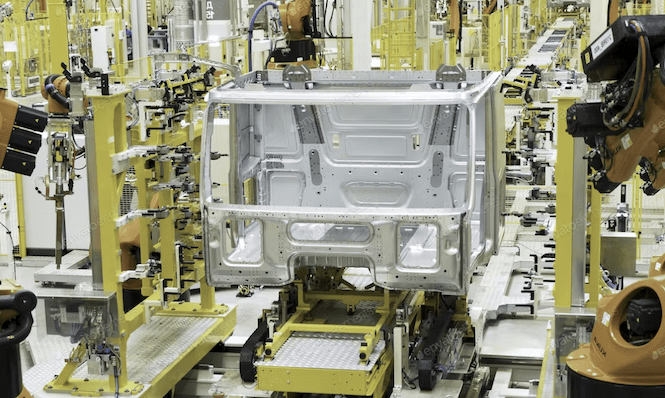

Where gas springs can be found within the industrial automation sector

Motion control solutions, such as gas springs and dampers, can be used in a wide variety of ways within the industrial automation and machinery sector. The selection below is just a few:

- Food production (fixed force stainless steel compression gas struts using food safe oils)

- Packaging equipment (hydraulic dampers – Cam-Shoc)

- Material handling equipment

- Part handling machinery

- Robotic calibration

- Conveyor systems (adjustable force gas struts – Vari-Lift)

- Control system cabinet access

How our products work in the industrial automation sector:

At Camloc Motion Control, we understand the vast number of potential applications that can be found within the industrial automation and machinery sectors. We have taken the time to ensure we offer a wide range of gas springs and hydraulic dampers that enable simple yet effective design and manufacturing. In doing so, we can provide a wide variety of innovative solutions to meet the specific needs of our customers.

Hydraulic Dampers

The reliability and longevity of your equipment are both critical to the success of a project in the industrial automation sector. To help ensure that our customers’ equipment continues to perform at the levels required, our range of hydraulic dampers, Cam-Shoc, are often found controlling and absorbing the kinetic motion of the machinery they’re used on, protecting both operators and equipment.

For example, when creating a solution that is suitable for use in food sealing machinery, protecting the machine from impact forces is paramount to its reliability and longevity. Our hydraulic dampers are available in a wide range of types, damping characteristics, and sizes that can be tailored to each specific machine and application. The damper absorbs the kinetic energy and provides a smooth, seamless environment for the rest of the equipment to operate in.

Stainless Steel and Food Safe Fixed Force Compression Gas Struts

With cleanliness and consumer safety of paramount importance in food manufacturing automation equipment, the ability to adapt applications to each customer’s specific requirement is critical. Our range of products can be specified using 316L stainless steel construction and with food-safe oils where necessary. Our Swift and Sure range of fixed force compression struts are often found in food manufacturing environments where the ability to safely lift, lower and control the movement of the equipment is required.

We believe you cannot engineer the highest-quality motion control solutions without first using materials of the highest quality. When combined with state-of-the-art manufacturing facilities and the hard work of our talented team, this means we can confidently state that our superior product quality is what sets us aside from our competition. Our 316L Stainless Steel option is also indicative of this, providing extra corrosion resistance and cleanliness for use in these types of environments.

Bespoke Design

At Camloc Motion Control, all our products are designed to meet our customers’ exacting needs and standards, and our team of experienced engineers will work with you to provide gas spring and hydraulic damper solutions. We pride ourselves on our service to customers, with design engineers on hand to work with you using the latest CAD/CAE techniques. Recognising that no two applications are the same, we provide engineered solutions to meet your exact requirements.

For more information about our range of gas struts and dampers, visit our product page.

Talk to one of our team on +44 (0)116 274 3600 or fill in the Contact Us form and we will get back to you.

How Camloc operates

Understanding the complexities of projects involving manufacturing in the industrial automation and machinery sector is what our team does best. Boasting a 99% on-time delivery rate and competitive lead times – coupled with our expert technical advice and engineering support, is what separates us from the competition.

Our expert team have extensive experience within the industrial automation sector, working closely with industry leaders to successfully deliver a variety of projects. Whatever your project requirements, we’ll be with you every step of the way.

Continuous investment in our staff and the latest hardware keeps us at the forefront of our industry, ensuring we continuously adopt the latest manufacturing processes from our facility, and we successfully problem-solve for our customers. We continue to enhance and evolve our production processes using lean manufacturing methods, something we have been doing since 2001.

We deliver high-quality products that cover a wide range of industry sectors, across the UK, USA, Europe and around the world.

“Working with Camloc is easy and feels like working with other members of our team, they really understand how we work and what we want to achieve.”

James Smith – Industrial Sales Manager – Clarendon Specialty Fasteners.