Although it looks similar to a pneumatic or hydraulic cylinder, a gas spring is different because of the fact that it does not require an external energy source to create movement. This is because a gas spring is a completely closed system and once manufactured and charged with inert nitrogen gas, no additional gas is introduced to the system.

In gas springs, the pressure on either side of the piston remains equal whether it’s fully extended or fully closed. This again is different to a hydraulic or pneumatic cylinder that requires a pressure differential across the piston in order to move.

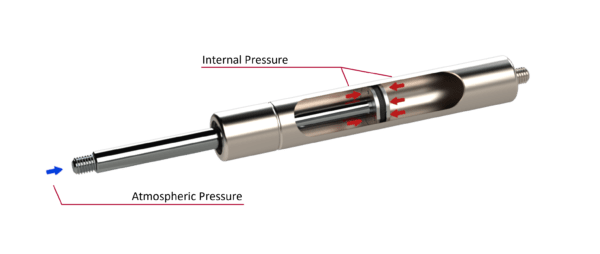

So, if this is the case, how does it work if no further gas is introduced, and the internal pressure remains equal? The works because the gas strut extends and this is due to the difference in cross-sectional area of the rod where the gas is unable to exert any pressure. It is the difference between the nitrogen gas pressure acting on the internal face of the rod, and the atmospheric pressure acting on the external end of the rod that causes it to extend.

As the rod is pushed into the tube the available volume is reduced, gas is compressed and the internal pressure increases, this compression creates the spring like behaviour. An orifice in the piston that is attached to the rod allows the flow of gas across the piston and controls the extension speed.