What do the mounting brackets do?

The range of Camloc gas springs is complimented by specially-designed mounting brackets. Together, the extensive array creates a wide range of easy to-assemble fixing options to suit your application.

Our gas strut mounting brackets suit our extensive range of end fittings, creating a wide range of easy-to-assemble fixing options. Available in a wide range of styles, including 90°, flat and raised, the brackets are drilled to accept a variety of fixings, making it easier to fasten to timber and steel frameworks using screws or dowels.

The range of Camloc gas springs is complimented by specially-designed mounting brackets. Together, the extensive array creates a wide range of easy to-assemble fixing options to suit your application.

The mounting brackets are manufactured in carbon steel with zinc and clear passivate. The components achieve a minimum of 72 hours of salt spray testing under ASTM B117. Additionally, a small number of brackets are available in stainless steel. They are designed for ease of assembly with either ball pins or threaded pins to suit our wide range of end fittings. The brackets combine compact design with strength – offering an extensive force range capability.

We offer a bespoke service, and our team of experienced engineers will work with you to provide gas spring solutions, even if it is outside the standard type and sizes.

We pride ourself on our service to customers, with design engineers on hand to work with you using the latest CAD/CAE techniques. Recognising that no two applications are the same, we provide engineered solutions to meet your exact requirements.

Our products page has more information about the various range of solutions that we provide.

Talk to one of our team on +44 (0)116 274 3600 or fill in the Contact Us form and we will get back to you.

We offer a range of brackets to complement our range of gas springs and end fittings.

Our most popular mounting brackets are available in carbon and stainless steel. Available in a wide range of styles, including 90°, flat and raised, the brackets are drilled to accept a variety of fixings, making it easier to fasten to timber and steel frameworks using screws or dowels. They are designed to accept DIN/ISO standard fixings.

Manufactured in carbon steel with zinc and clear passivate, all our gas strut mounting brackets achieve a minimum of 72 hours of salt spray testing under ASTM B117. They are designed for ease of assembly, with ball pins for ball joints and ISO thread for threaded pins for lock nuts and split pins. The brackets combine compact design with strength – offering an extensive force range capability.

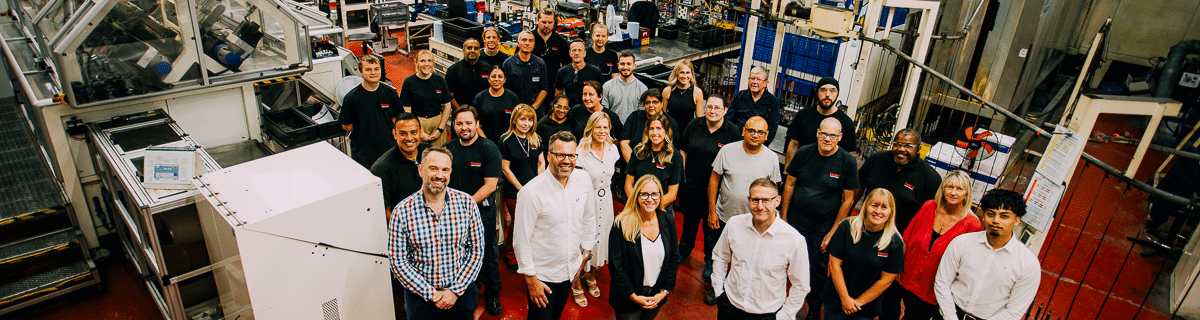

Continuous investment in our staff and the latest hardware keeps us at the forefront of our industry, ensuring we continuously adopt the latest manufacturing processes from our facility, and we successfully problem-solve for our customers. We continue to enhance and evolve our production processes using lean manufacturing methods, something we have been doing since 2001.

We deliver high-quality products that cover a wide range of industry sectors, across the UK, USA, Europe and around the world.

Get in touch via our Contact Form or call us on +44 (0)116 274 3600

To access more information on installing, maintaining and technical data about gas spring, damper and motion control solutions – head to our Help Centre.

We’re here to answer all your questions around the correct application of gas struts and dampers.

3D CAD model downloads for our range of gas strut mounting brackets.