In this blog post, we’re going to explore how and why gas struts can prevent accidents and injuries, whether that is reducing the risk of repetitive strain injuries in hospital porters, or supporting engineers to do their best work in a safe environment.

How gas struts provide safety

Controlled Movements: Gas struts offer controlled and predictable movements, ensuring that equipment operates in a smooth, controlled manner. This helps prevent sudden or uncontrolled motions that could potentially lead to accidents or injuries. For example, equipment lids or hatches fitted with gas struts can be opened or closed in a controlled manner, preventing them from abruptly slamming shut and causing harm.

Reduced Risk of Falling Objects: Gas struts can be used to hold equipment parts or components in specific positions. By supporting the weight and preventing unexpected movements, gas struts minimise the risk of objects falling or dropping. This is particularly important for heavy or large equipment components that could cause serious injury if they were to fall.

Enhanced Operator Safety: Gas struts in ergonomic applications prioritise operator safety. For instance, workstations or machinery that require height adjustments can be equipped with gas struts to enable easy and safe positioning. This prevents operators from straining themselves or adopting awkward postures while adjusting, reducing the risk of musculoskeletal injuries.

Protection Against Accidental Closures: Gas struts can be utilised to counterbalance equipment lids, doors or panels, preventing accidental closures that can cause injuries. By providing the appropriate amount of force to keep these components open, gas struts ensure they remain in position, even in situations where an operator inadvertently releases or loses control of them.

Improved Ergonomics: Gas struts contribute to overall ergonomic improvements by enabling easy and smooth adjustments of machinery or equipment. This reduces physical strain and fatigue for operators, minimising the risk of long-term musculoskeletal disorders. Improved ergonomics result in a safer and more comfortable working environment, ultimately lowering the likelihood of accidents or injuries.

Tailored Performance: Gas struts can be customised in terms of load capacity, stroke length and damping characteristics to match specific equipment requirements. This allows for precise control over the movements, ensuring optimal safety. By tailoring the performance of gas struts to the specific application, the risk of accidents and injuries can be further minimised.

Gas struts can significantly improve the safety of various industrial equipment by preventing unsafe movements. From heavy machinery lids and access doors to adjustable workstations and medical equipment, the potential for gas struts to make workplaces safer is vast.

For example, gas struts are often employed to support and control the opening and closing of heavy machinery lids or covers. Without gas struts, these lids may pose a significant risk due to their weight and the potential for abrupt or uncontrolled movements. Gas struts ensure that the lids open and close smoothly, reducing the risk of accidents or injuries caused by sudden drops or unexpected movements.

Gas struts are commonly found in medical equipment, such as hospital beds, examination tables and diagnostic equipment. These struts enable smooth adjustments and controlled movements, providing comfort and safety for patients and healthcare professionals. Gas struts are especially important in applications where precise positioning, stability and ease of use are critical.

By using gas struts in these examples, the risk of accidents and injuries can be significantly reduced. The controlled and smooth movements provided by gas struts offer enhanced safety, preventing sudden drops, unexpected closures and uncontrolled motions that could otherwise lead to workplace incidents and harm to operators or users.

Final thoughts

Gas struts help prevent accidents and injuries by providing controlled and smooth movements in industrial equipment. They contribute to enhanced safety by offering controlled motions, reducing the risk of falling objects, protecting against accidental closures, improving ergonomics and providing tailored performance to suit equipment requirements. By incorporating gas struts, industrial workplaces can create a safer environment for operators and reduce the potential for accidents and injuries.

How Camloc operates

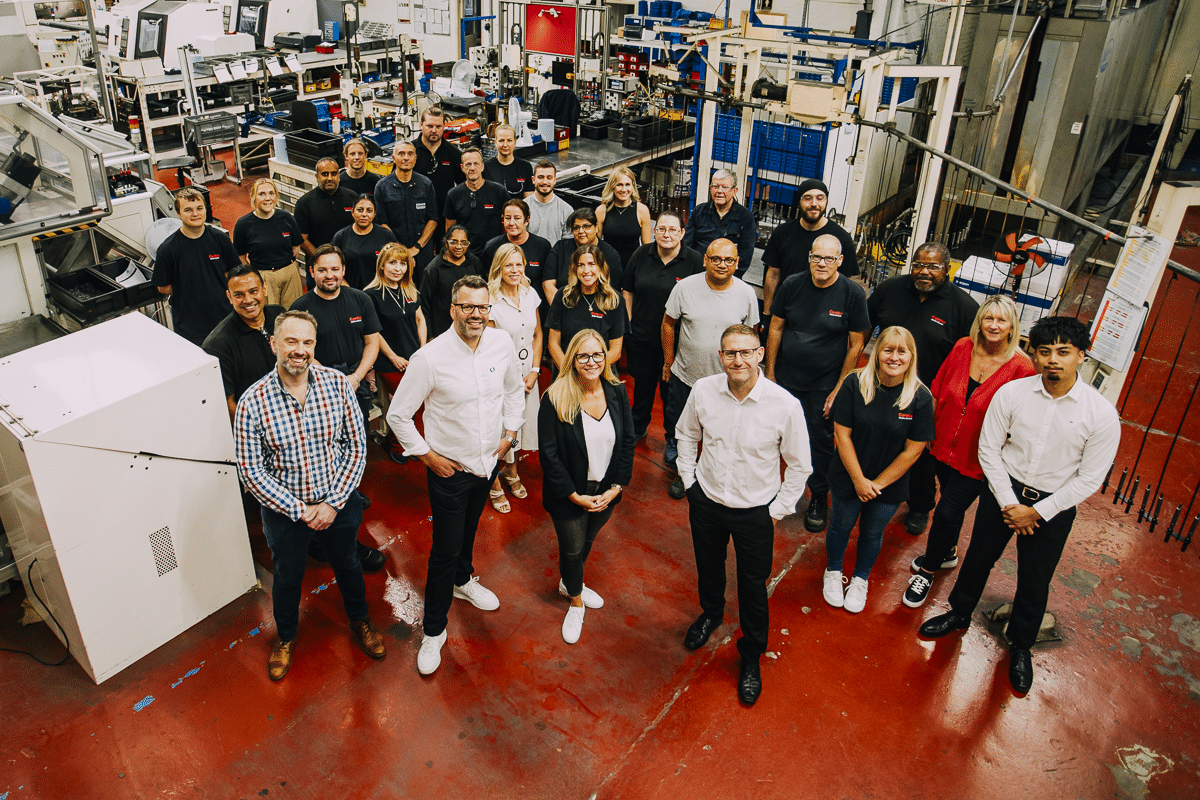

Our expert team have extensive experience within a wide range of sectors, working closely with industry leaders to successfully deliver a variety of projects.

Whatever your project requirements, we’ll be with you every step of the way. Continuous investment in our staff and the latest hardware keeps us at the forefront of our industry, ensuring we continually adopt the latest manufacturing processes from our facility, and we successfully problem-solve for our customers.

We continue to enhance and evolve our production processes using lean manufacturing methods, something we have been doing since 2001. We deliver high-quality products that cover a wide range of industry sectors, across the UK, USA, Europe and around the world.

For guidance on installing, mounting or maintaining gas struts, please see the Help Centre section of our website.

What to do now

Get in touch with us today.

We can help you with all your manufacturing and engineering needs. if you can’t see what you’re looking for on our website, don’t worry, we will still be able to do it.

Just give us a call or send us an email with your brief or requirements, and we will get your project moving. Make sure you’re following us on Facebook, Twitter, LinkedIn and YouTube so you never miss an update from us.