What is a self-centering damper?

A self-centering damper has a unique function that enables movement forwards and backwards in both extension and compression, with a controlled rate of return from either direction to a neutral, mid-stroke position.

These kinds of dampers are non-cavitating, which means they can be mounted in any position without loss of function. This damper is the overwhelming choice on all applications where the end-user interacts with the damper due to its superior ‘feel’.

What are the benefits?

This variety of damper is a cost-effective product offering a solution for a range of engineering situations. It’s available in both carbon and stainless steel, in an extensive range of sizes, and end fittings for a wide variety of applications. These dampers can be found in a seat suspension system application where no direct end-user interaction is required with the damper.

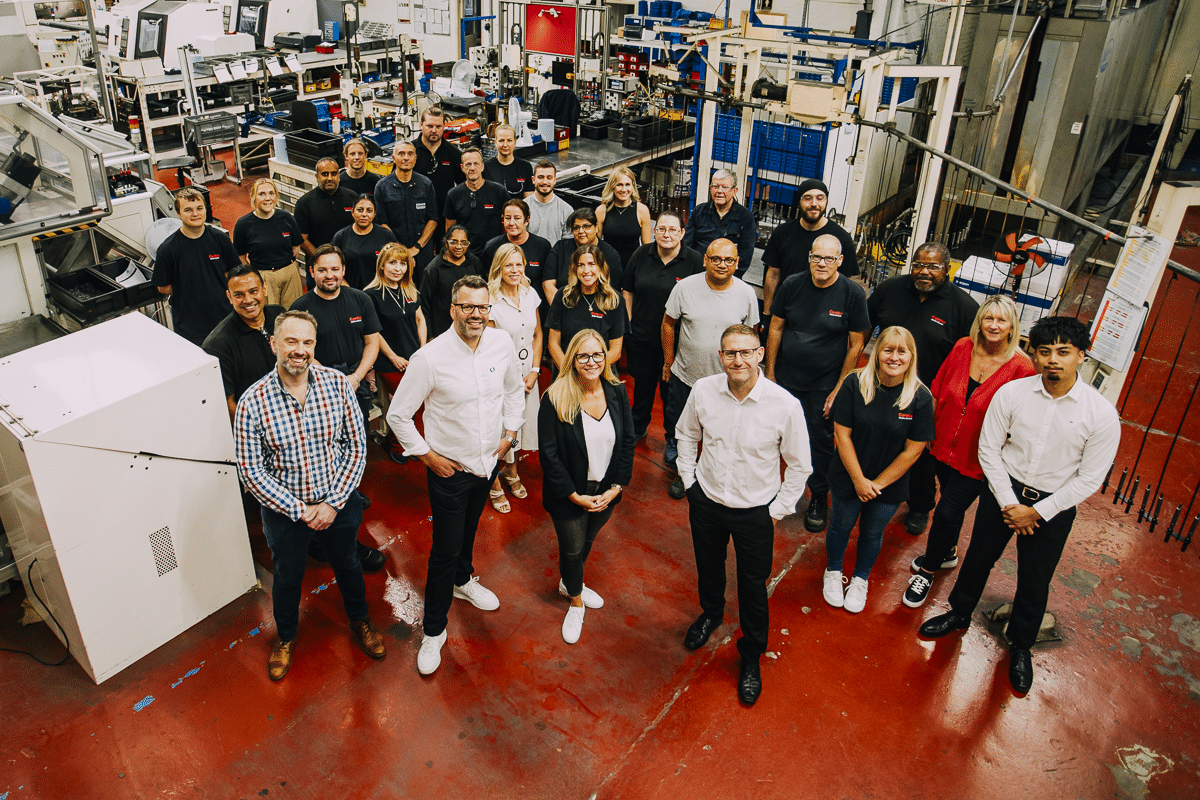

With our team of skilled engineers, who love a challenge, we set about creating a refined and improved product compared to those previously found in the market. During a period of four months, we had researched, designed, built and tested our own Self-Centering Damper, known to us as the ‘Cam-Shoc SCD’ range.

“There’s really nothing quite link sinking your teeth into a challenge and there’s no challenge quite like designing an entirely new motion control solution. Don’t get me wrong, it’s hard work and there are times where you have to head back to the drawing board but it’s amazing when it all pulls together.” Gagen Chatha, Design Engineer at Camloc Motion Control.

How we overcame any challenges

There were a few challenges with this product. Our first task, as with any project like this, was to gather the engineering team around a large whiteboard and brainstorm ideas on how we would make this product work within the customer’s very tight packaging confine.

Secondly, we were aware from customer feedback that, due partly to the aggressive environment (dust/dirt/moisture etc), the design of their earlier product was prone to corrosion.

The third issue we faced was how we would build and assemble these parts. With standard gas struts and dampers, gassing is one of the final processes and we don’t have to deal with compressing a partially-built product in order to complete the build.

We successfully addressed all these issues throughout the development process, and delivered a product that would fit within the customer’s space envelope.

We addressed the issues of corrosion, not only in how we designed the product (fully enclosed, eliminating water traps etc) but also in the option of a fully stainless steel version. We also designed and built a new assembly bench for our production team to build the product.

This is an entirely self-contained motion control solution. It has the characteristics of a traditional damper which, when partnered with a small change in force as it extends and retracts, provides a diverse, controlled rate of movement.

If you have a project where an item needs to be pushed forward or pulled backwards then return to a central ‘neutral’ position, our self-centering damper could be the answer.

“We work closely with our customers at every stage, from initial design through to product testing, manufacture and distribution. This also includes produce development and innovation, meaning that when we see that something needs designing and creating, we jump right on to that. It’s at the heart of what we do here at Camloc.” Matt Warne, Joint Managing Director and co-owner at Camloc Motion Control Limited.

We have created a range of sizes, so finding the right damper for your application is simple and straightforward. Where Camloc comes in We manufacture a wide range of product types which help with lifting, lowering and counterbalancing weights. Our customisable products meet the needs of each and every product or application. This service runs throughout the project, from design and testing, to manufacture and distribution. Our continuous commitment to quality means we always meet the highest industry standards through a product range that is manufactured here in the UK. Our location also enables us to provide short delivery lead times, and a promise to deliver your order on time and within budget. Whatever you are trying to achieve with gas struts, our team of experienced engineers are on hand to help you succeed, every step of the way.