Mounting Orientation

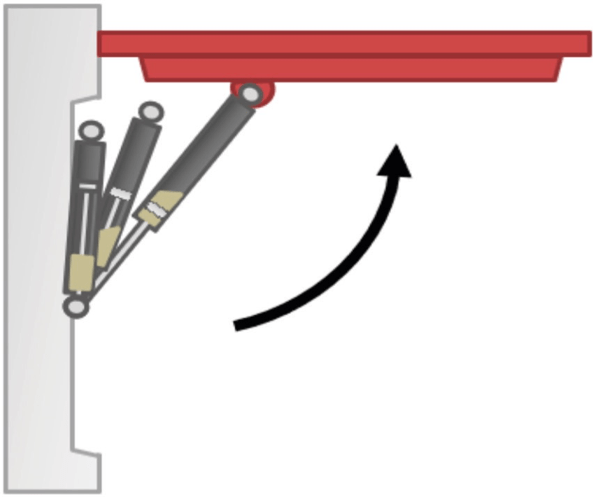

As a rule, Camloc’s preferred mounting is the ‘Push Up’ design orientation.

All our customers receive free technical advice on every project, with dedicated engineering support from concept to delivery.

Ask the ExpertsThere are two differing mounting orientations available to the designer, these are ‘Push Up’ and ‘Flip Over’ mounting. In both cases, it should always be mounted “rod down” when in the fully closed position to ensure proper lubrication of the seal package.

As a rule, Camloc’s preferred mounting is the ‘Push Up’ design orientation.

This type of mounting can be identified by the fact that the end at the lowest point when closed, remains in its lowest position when fully open. It can also be identified by the moving mounting point being located closer to the hinge than the fixed mounting point.

Unless a means is utilised to lubricate the rod, then the strut should always be mounted rod down to ensure proper lubrication of the main seal. The main drawback of this mounting position is the additional strength required in the application being lifted, particularly the hinge, this is due to increased cantilever of the lid from the gas spring support.

The major advantage with this type of mounting and rod down orientation is that it provides consistent damping at the end of the stroke. This is due to oil always being at the bottom of the tube; thus, damping will always occur at the same point in the lift cycle.

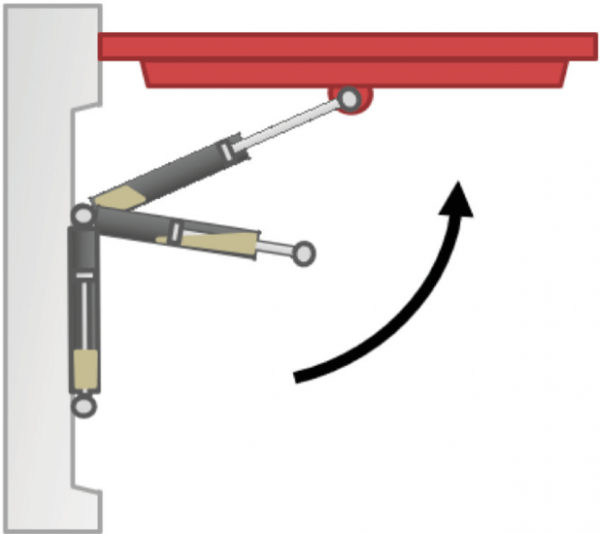

This type of mounting can be identified by the end at the lowest point of the strut when closed rotates to the highest point when fully open. It can also be identified by the moving mounting point being located further away from the hinge than the fixed mounting point

Unless a means is utilised to lubricate the rod then the spring should always be mounted rod down to ensure proper lubrication of the main seal in the closed position.

The main drawback of this mounting position is the lack of damping control throughout the stroke.

At the start of the stroke the oil is at the bottom around the main seal, as the spring passes the horizonal position the oil begins to run down the tube towards the tube end, along this point it will meet the piston moving up through the tube. When the piston meets the oil the extension of the spring will be slowed until the oil has passed through, then at this point the extension speed will increase and it will reach the end of the stroke with no damping.

The advantage of this design is that it places less strain on the hinges than the push up design.

Our friendly team are more than happy to help. Call +44 (0)116 274 3600.

Tell us about your project