How do gas struts work?

The basic principle of a gas spring is the same as a mechanical coil spring. That is because both devices have been designed and manufactured to store energy. However, the main difference is that. rather than straining the material that makes up the coil spring, a gas spring stores energy by compressing the nitrogen gas contained inside.

Although a gas spring looks similar to a pneumatic or hydraulic cylinder, it is different as it doesn’t require an external energy source to create movement. A gas spring is a closed system and, once manufactured and charged with inert nitrogen gas, no further gas is introduced to the system for it to operate.

With a gas spring, the pressure on either side of the piston remains equal, whether it’s fully extended or fully closed. Again, this is different to a hydraulic or pneumatic cylinder that requires a pressure differential across the piston in order to move. So, if it’s the case, how does it work if no further gas is introduced, and the internal pressure remains equal?

The reason the gas strut extends is due to the difference in cross-sectional area of the rod where the gas is unable to exert any pressure. It is the difference between the nitrogen gas pressure acting on the internal face of the rod, and the atmospheric pressure acting on the external end of the rod that causes it to extend.

As the rod is pushed into the tube, the available volume is reduced, gas is compressed and the internal pressure increases. This compression creates the spring-like behaviour. An opening in the piston that is attached to the rod allows the flow of gas across the piston and controls the extension speed.

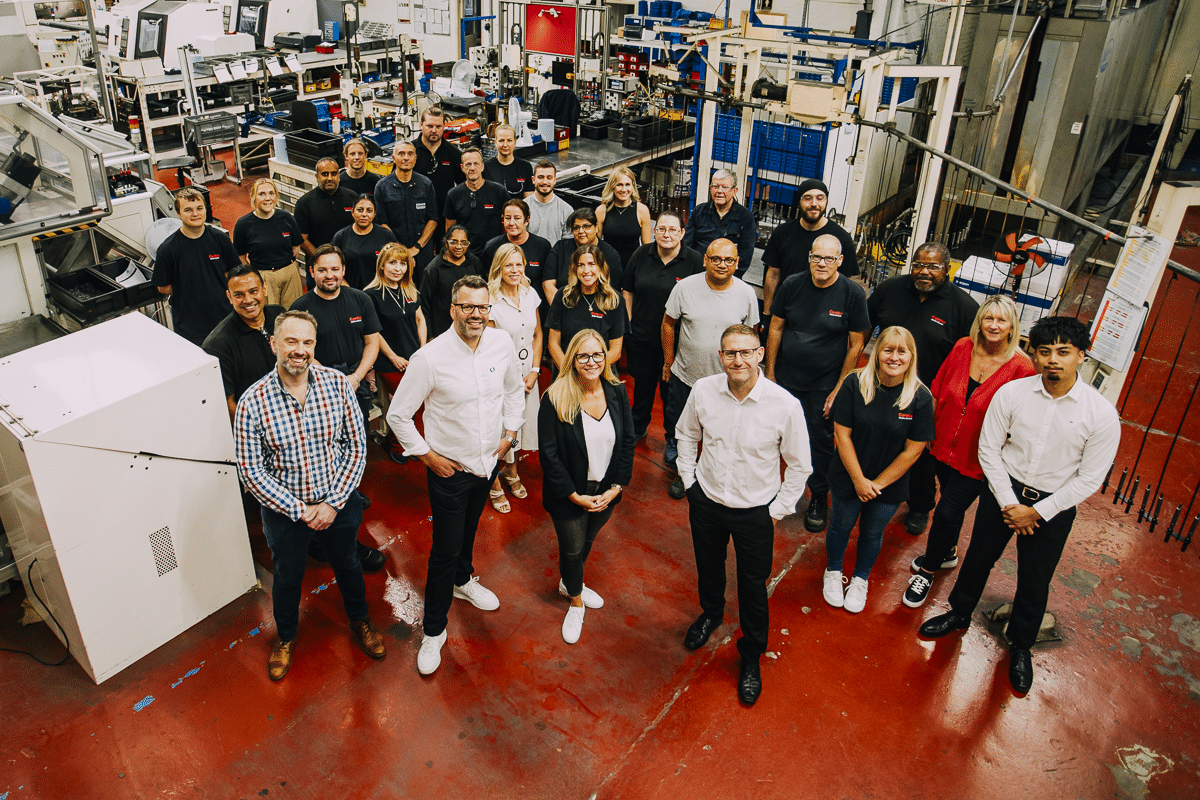

“At Camloc Motion Control, we take immense pride in helping our customers at whatever stage they are at in their project. We often have clients coming to us when they’ve hit an obstacle in their engineering journey, but our team of engineers are great problem solvers and we like to get stuck in and do the best work for our customers,”

Matt Warne, Joint Managing Director and co-owner at Camloc Motion Control Limited

Where we come in

We manufacture a wide range of product types which help with lifting, lowering and counterbalancing weights. Our customisable products meet the needs of each and every product or application.

This service runs throughout the project, from design and testing, to manufacture and distribution. Our continuous commitment to quality means we always meet the highest industry standards through a product range that is manufactured here in the UK.

Our location also enables us to provide short delivery lead times, and a promise to deliver your order on time and within budget. Whatever you are trying to achieve with gas struts, our team of experienced engineers are on hand to help you succeed, every step of the way.

Our Help Centre is a useful resource that aims to answer your questions about our products and how to use them, browse this resource here.

How Camloc operates

Our expert team have extensive experience within a wide range of sectors, working closely with industry leaders to successfully deliver a variety of projects. Whatever your project requirements, we’ll be with you every step of the way.

Continuous investment in our staff and the latest hardware keeps us at the forefront of our industry, ensuring we continuously adopt the latest manufacturing processes from our facility, and we successfully problem-solve for our customers. We continue to enhance and evolve our production processes using lean manufacturing methods, something we have been doing since 2001.

We deliver high-quality products that cover a wide range of industry sectors, across the UK, USA, Europe and around the world.

For guidance on installing, mounting or maintaining gas struts, please see the Help Centre section of our website.