Investment in a Second CNC Lathe to Further Enhance Production and New Product Development Capabilities

We continue our mission for growth, with further investment in a second CNC Lathe machine to increase production capability and flexibility.

The DMG MORI Sprint 32|8 is similar to the Lathe machine which arrived in September 2017.

Priding ourselves on our capability to design and manufacture bespoke gas springs and dampers to meet exacting requirements of our customers, the new machine enables improved flexibility to fulfil this mission.

The new lathe arrived on 7th January, 2019, becoming fully operational and going into action on 16th January, 2019.This being yet another major advancement within our business, to ensure we remain at the forefront of our industry.

“Following the proven success of the first CNC Lathe, we decided to bring forward the investment in the second” explains Technical Director, Matt Warne.

“Having access to a second lathe has enabled us to bring forward new product development, plus improve our flexibility to tailor customer specific solutions. Reducing specialist component lead-times means we are better able to meet customer needs with this being another step forward in adapting solutions to meet customer requirements” added Matt.

More Blogs

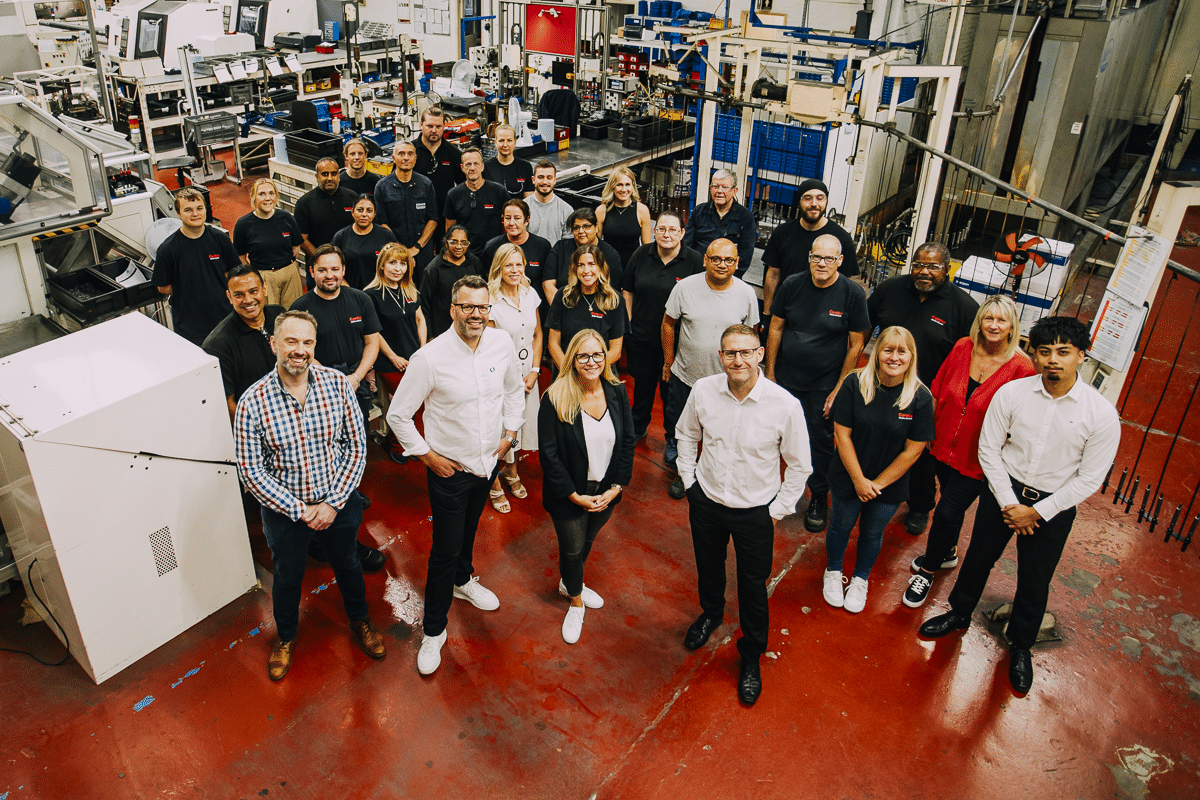

Camloc marks beginning of new four-day working week with national employer award

Camloc Motion Control is delighted to announce that we are moving to a four-day working week. What that immediately means for our customers is that there will be no change to the exceptional service you’ve come to expect from us. What it means to our employees is that, by enhancing their wellbeing and by supporting sustainable practices, a four-day working week will not only benefit them but, in turn, our customers, too. It’s a win-win situation for our customers and workforce alike, and that has been recognised by Camloc being awarded a Silver Standard accreditation by the The 4 Day Week Foundation, of which we’re very proud.

Why Camloc’s personal approach and ‘Made in Britain’ status are valued by potential new customers

When talking to potential new customers, two key points are very often fed back to us: The fact that our engineers themselves handle enquiries, giving more of a personal touch, and that we are Made in Britain accredited – both carry a lot of weight. In this blog, we’ll discuss why we’re proud to showcase our Made in Britain mark, and why Camloc Motion Control put so much stock into delivering the very best experience we can to potential new customers.

Gas Struts Unleashed: Our Top 10 Gas Strut PDF Downloads

At Camloc, we offer you bespoke and made-to-measure gas struts, but we also aim to provide you with all the information you might need when considering using a gas strut in your application. We have a wide range of gas struts and additional products that we are confident will meet your needs, and to help you with the design process, we have created a range of downloadable PDFs to inform your choice. So, what is a gas strut and how can it help my application?